Fix This First: Cosmetic Cup

Recently we had a customer approach us for a high end cosmetic product. Right away, we saw some issues with the design.

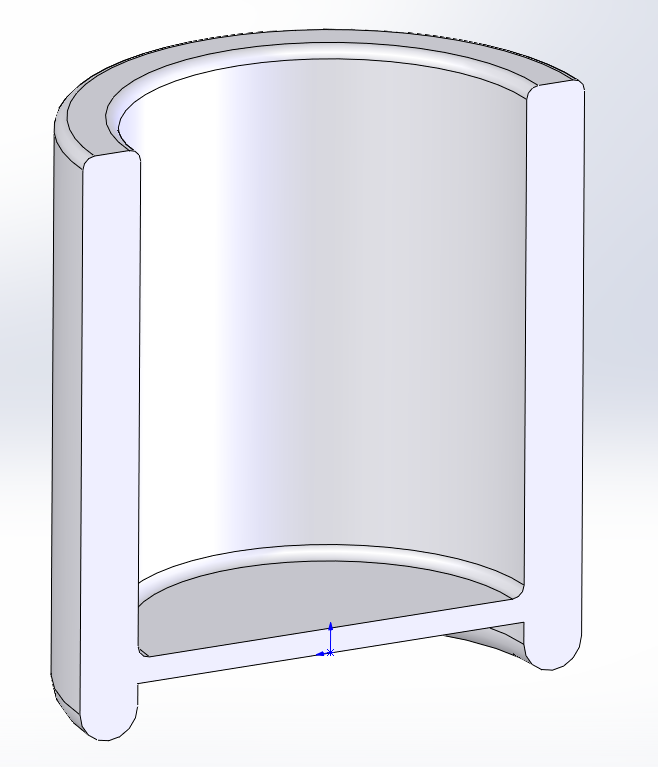

To maintain aesthetics, the only area we could inject into was the bottom which was too thin for molding. The container itself had thick side walls, and trying to inject directly into a thin bottom would have caused sinking in the thick side walls (Picture below for reference)

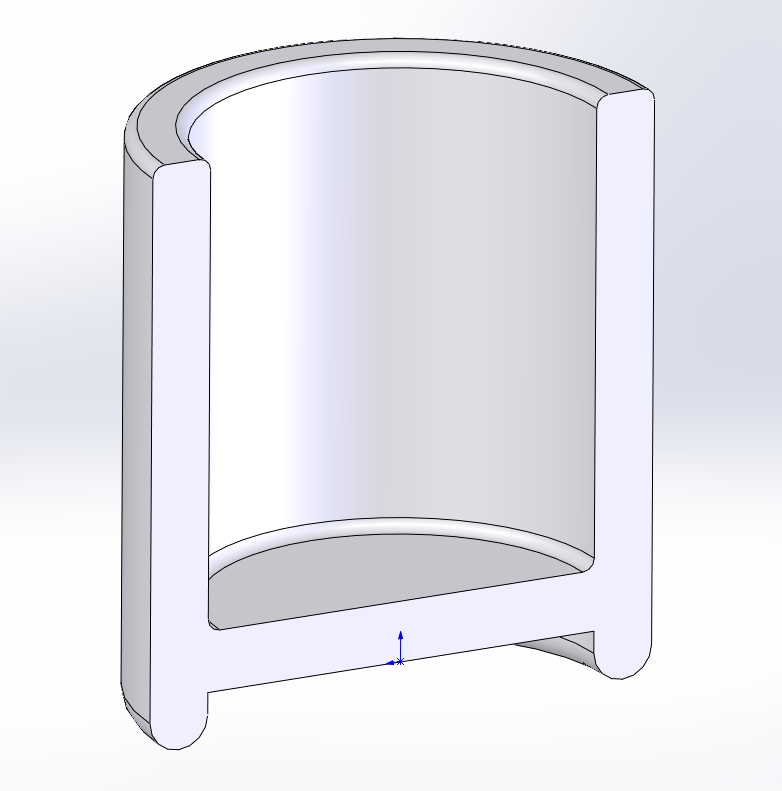

The solution we offered was to thicken the bottom, so the wall and base thickness would be more even.

Good molding practice suggests injecting into a thick wall, then filling in a thin wall. This strategy prevents issues like sink marks, warping, and non-fill that occur when molten plastic cools inconsistently or the flow stops prematurely.

In an ideal world everything would be the same thickness. If you get the wall thickness within reason, defects can be mitigated.