Fix this First: Glasses Case

This design is not ideal to make in the US.

This is a glasses case I’ve had for a while for my blue blocking lenses.

It’s a simple case. It does what it’s supposed to do. More than likely it was made overseas. However, if you wanted to make this exact product in the US, you will be paying more than is necessary.

What appears to be a simple design is actually more complex from a manufacturing perspective.

Shown below are explanations of manufacturing marks and a redesign for a more sustainable manufacturing process in the US.

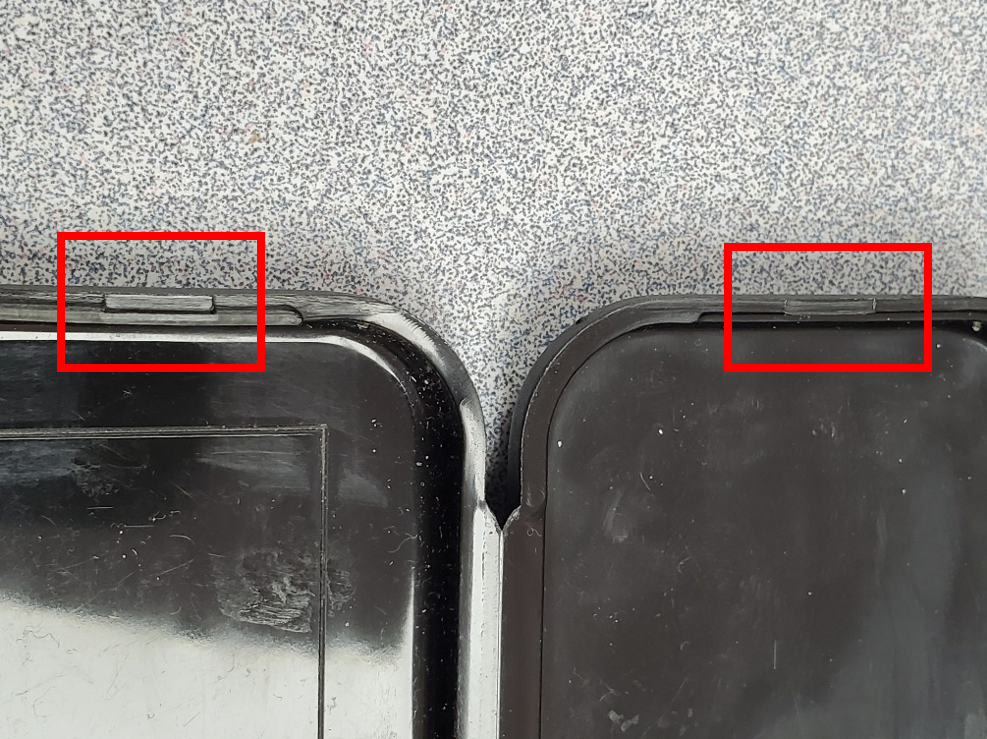

Ejector Pin Marks

Ejector pins push the part out of the mold. Because the part is hot and the plastic a little soft, these pins often press into the part leaving behind marks like the ones shown in the picture.

Automatic Slide?

External undercuts in the part design call for automatic slides or handload inserts in the mold. The flash highlighted here looks pretty uniform. I would guess this is evidence of an automatic slide.

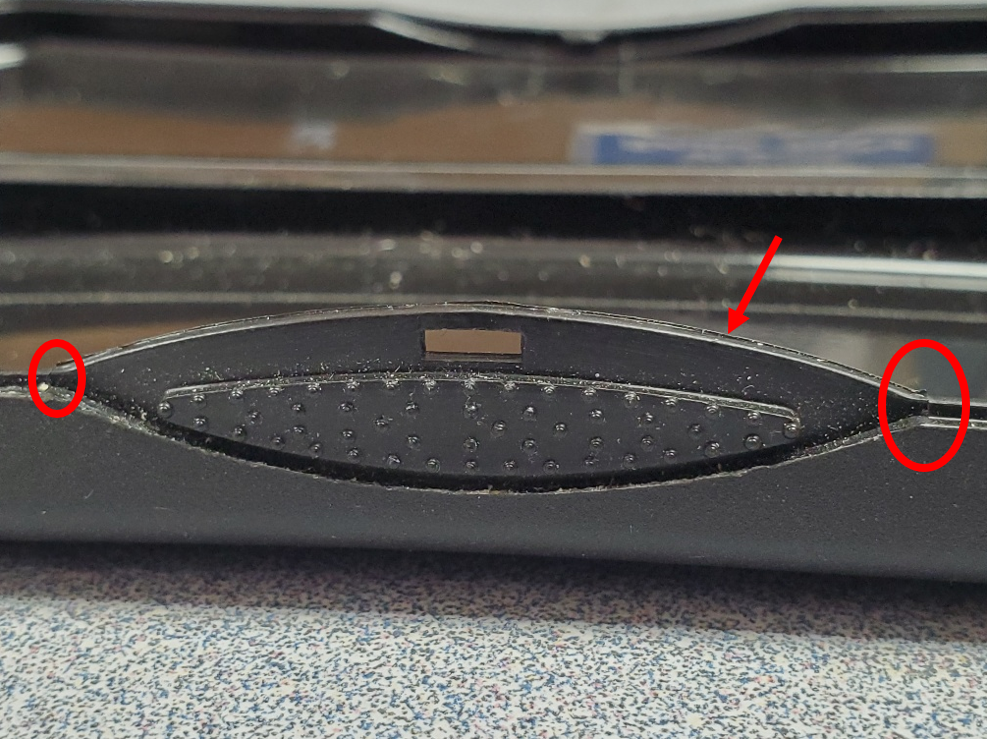

Evidence of Handload Insert

Internal undercuts are formed with lifters or handload inserts. Often because of limited real estate or budget, handload inserts are used. While you might save money in tooling, you may lose in part costs as now the part is operator dependent. Someone has to load and unload those inserts to form the part.

Further Evidence of Handload Insert

The flash here looks like it’s getting worse. A sign of handload inserts. Because an operator has to remove them and reinsert them for every part, sharp edges on the insert dull from handling.

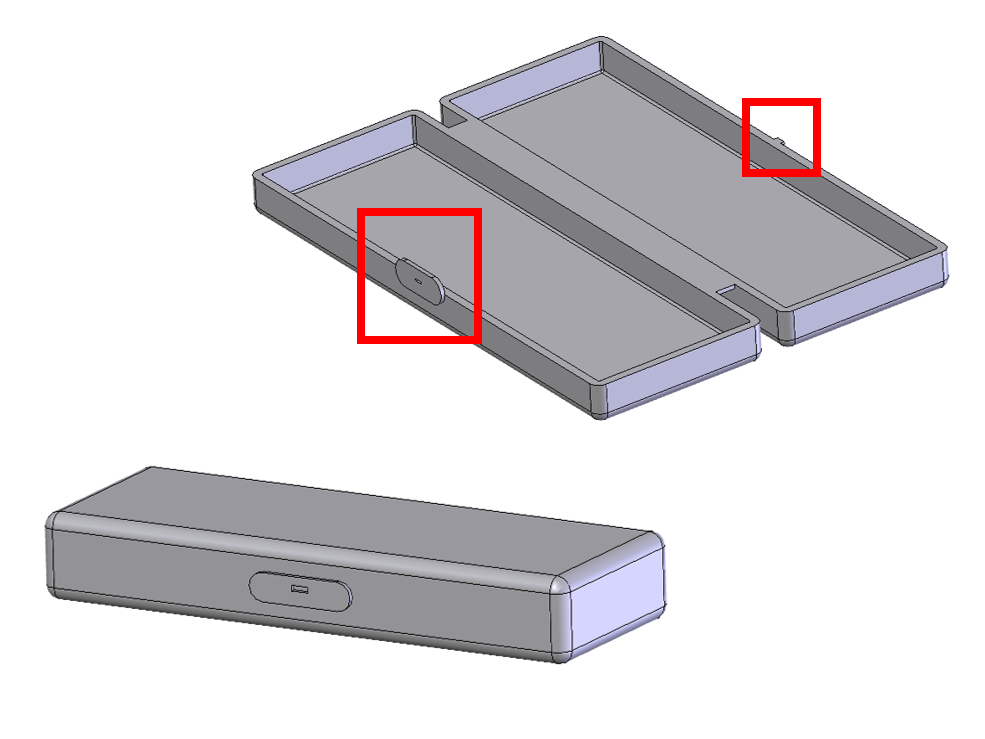

How we would have designed it.

To both minimize tooling and be able to produce parts without human intervention, the design shown is a sample of what we would have recommended.

From 1 internal undercut and 1 external undercut, we now have only 1 external undercut which can be produced with an automatic slide.

Without human intervention, this mold can now run unattended increasing molding capacity and reducing part costs.

Embossing the logo would also reduce the part cost further as opposed to pad printing.

Need input on your design?

We offer FREE design consultation hours for new customers with limited availability.

Stop guessing. Work with us to design something that will save your company time and money.

Contact us or send your project to info@bteplastics.com

Or, if you prefer, you can call me (Isaac) at 586-792-4119 ext. 5