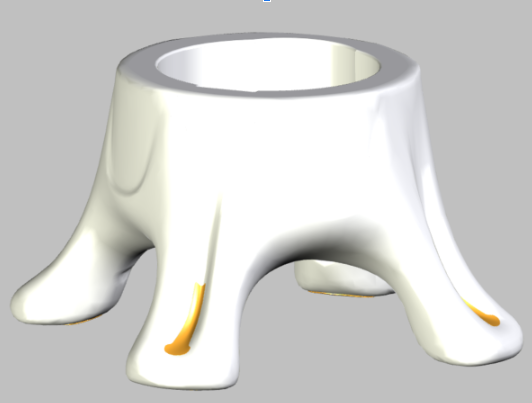

Fix This First: Luxury Condiment Holder

Plastic is in everything, so you never know what’s going to come across your desk. We recently received a web inquiry for a luxury condiment holder. The design was already effectively finished, and the customer did not want to deviate far from what they already designed, since it matched their brand.

Unfortunately, due to the shape of the condiment holder, the mold would not have a flat parting line that would be easy to hide. Understandably, the customer did not want a visible parting line. However, the cost to create a perfect match between the two halves of the mold would not justify the initial volume of the new product at launch. So we had a dilemma to solve!

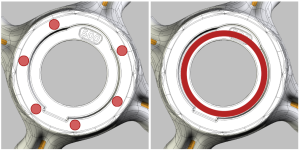

There were two versions of this design; the 500 and the 1000. In an effort to keep tooling costs lower for the initial launch, we considered options that involved sharing a mold base that allowed us to swap out inserts.

We suggested moving the part numbers’ location “500” and “1000” to eject the part with a simple ring ejector. Otherwise, ejecting the part without leaving marks would be a challenge. Beyond this, our problem-solving skills were put to work when we cored out the thick areas of the part. Due to the aesthetic preferences of the customer, our proposal was the best option, since putting ejector pins on the top surface would have diminished visual appeal in the design.

Despite our best efforts balancing price and part quality, the customer chose to pursue other options. Because the customer did not want to offer any flexibility in design, this made it impossible for us to meet their budget for this project. The final cost to build the tool was going to be around $23,000 for a single cavity mold with shared inserts, and we could have reduced the tooling cost by around $5,000 with our proposed changes.