Best Tool & Engineering Services

Comprehensive Injection Molding Services

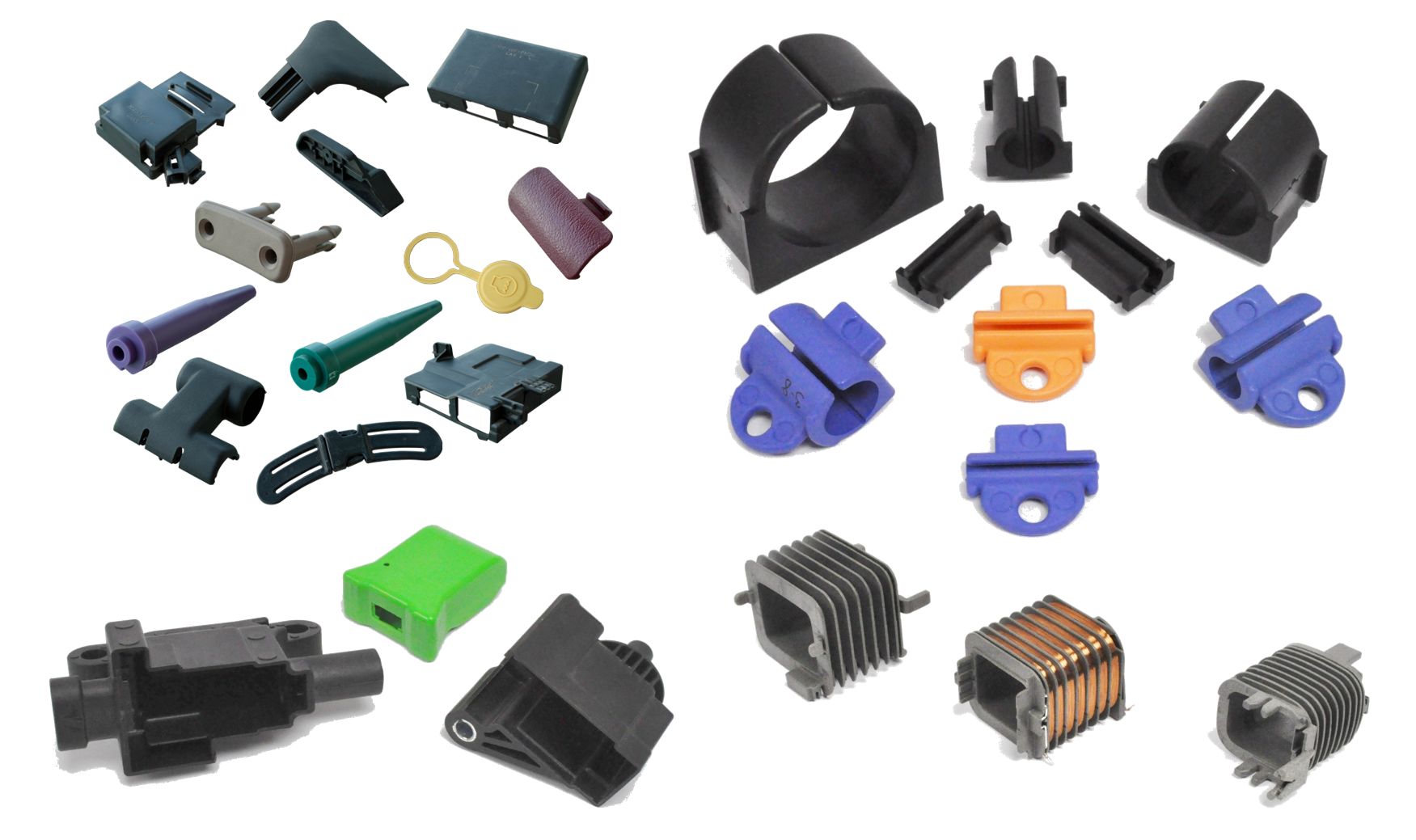

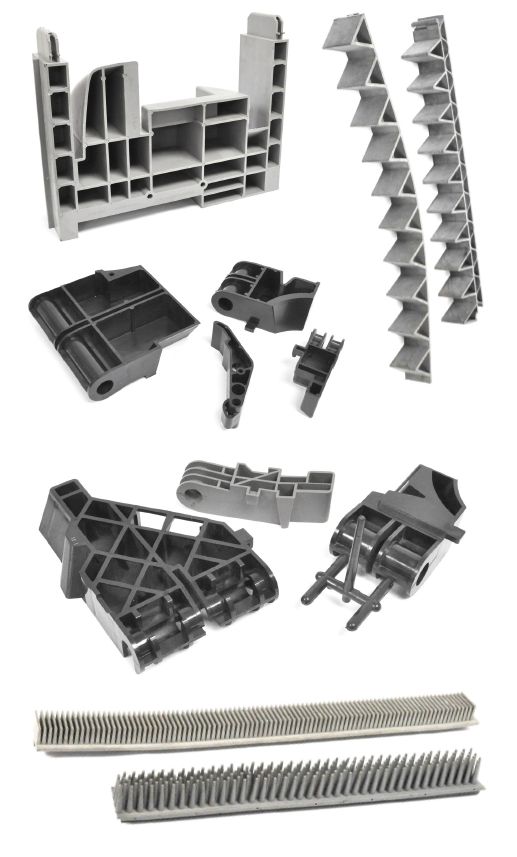

At Best Tool & Engineering, we offer end-to-end Injection Molding Services, including both precision Injection Mold manufacturing and high-quality plastic part production. Whether you need prototypes, short runs, or full-scale production, our team is ready to support your project at any stage.

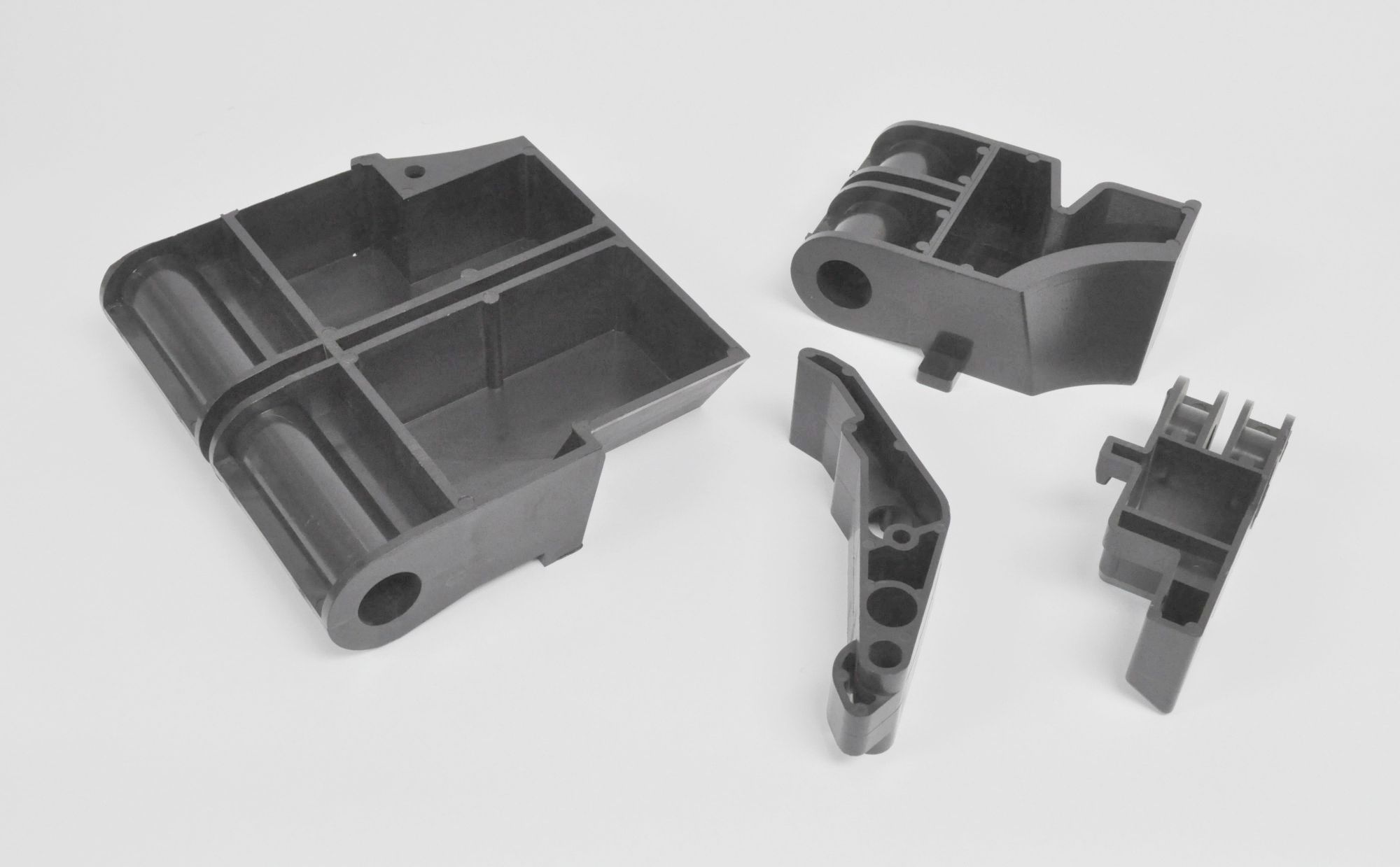

Aluminum Injection Molds for Low to Mid-Volume Production

Our specialty lies in Aluminum Injection Molds, ideal for low to mid-volume production runs—up to 250,000 parts. These molds offer a faster turnaround, lower upfront costs, and excellent durability for many applications.

Scalable Solutions for Growing Demand

When your production needs exceed 250,000 parts annually, we offer custom hybrid molds—a cost-effective alternative that adapts to growing demand without requiring a complete mold rebuild. For high-volume production in the millions, we’ll work with you to design and manufacture a robust steel mold built for long-term performance.

Cost-Effective Options for Innovators and Startups

Are you an inventor, entrepreneur, or someone needing production-quality parts in limited quantities? We understand that full mold investment isn’t always practical at early stages. That’s why we offer affordable, alternative solutions designed to deliver quality and flexibility without the high cost of traditional tooling.

Injection Molding Capabilities

Size Capacity

At our facility, we offer a wide range of injection molding services designed to meet diverse manufacturing needs. Our presses range in clamping force from 75 to 500 tons, allowing us to handle a variety of part sizes and complexities.

We accommodate shot sizes from 3 ounces up to 60 ounces, making it possible to produce everything from small, high-precision components to larger, more robust parts.

How to Calculate Shot Size for Your Part

To determine the required shot size for your molded part, use this simple formula:

- Measure the volume of your part (typically in cubic inches).

- Multiply the volume by the specific gravity of the plastic material you plan to use.

- Convert the result to ounces to find the appropriate shot size for production.

Example: If your part is 20 in³ and your material has a specific gravity of 1.2, your shot size is 24 oz.

Exceeding the 60 oz Shot Size?

If your calculated shot size is slightly above our 60-ounce capacity, don’t worry. We’re happy to review your part design and discuss potential options. This could include design adjustments, using alternative materials, or exploring multi-shot or sequential molding strategies.

Contact us today to speak with our engineering team and find the best solution for your project.

Additional Features

Best Tool & Engineering offers the following features for your product:

- Over-Molding: the process of molding over metals or other plastics. Typically used for knives with plastic handles and other products that use more than one material.

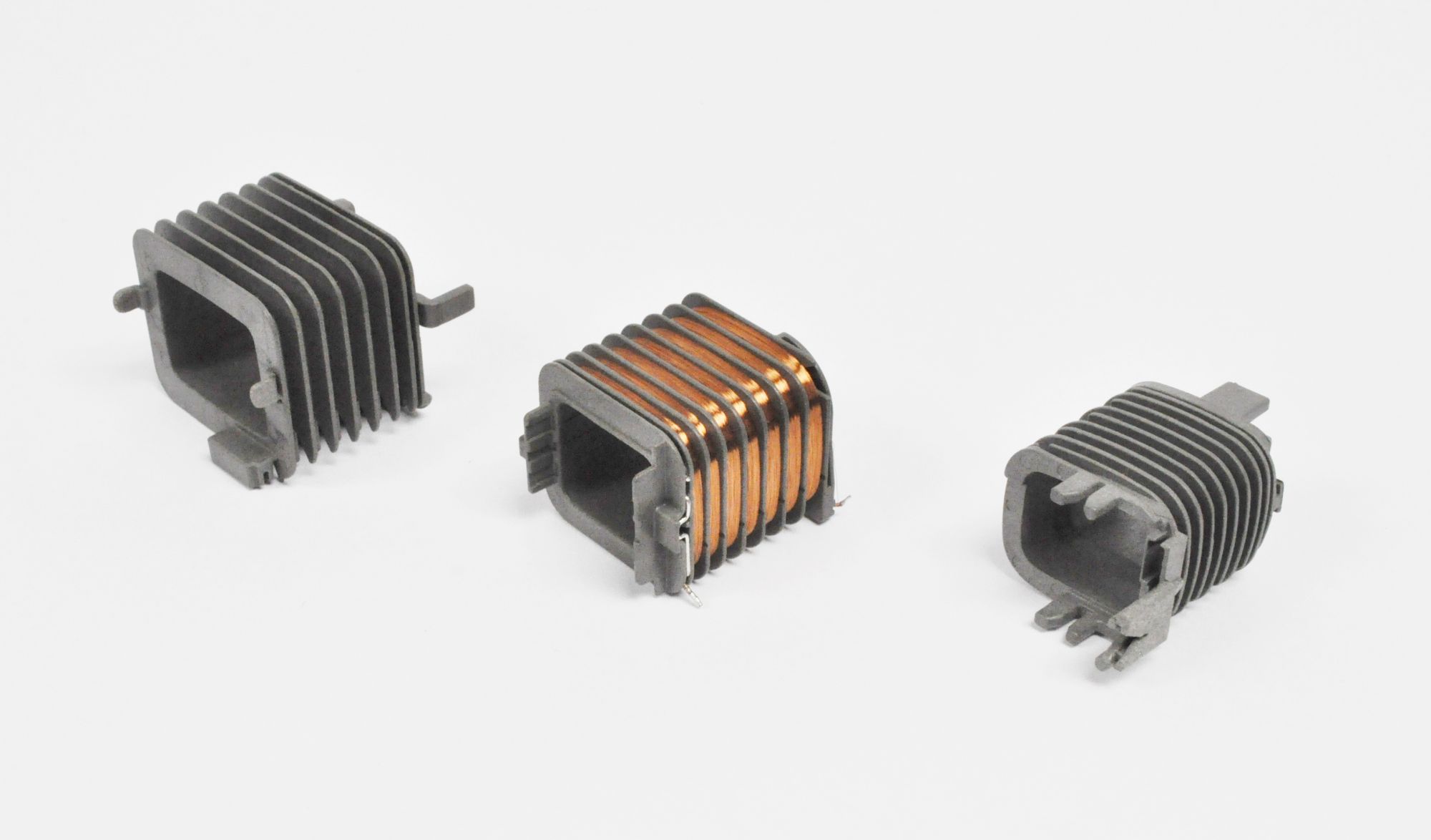

- Insert Molding: using Over-Molding techniques to incorporate inserts in your product for better fastening abilities.

- Living Hinges: plastic hinges that you would find on a pencil box for example.

- Different Finishes: Examples shown below.

Accepted Plastics

Injection Molding allows your product to be made from a wide variety of plastics and the color options can be endless. Below are some of plastics that can be molded.

| Abbreviated | Full Name | Typical Specific Gravity |

|---|---|---|

| ABS | Acrylonitrile butadiene styrene | 1.04 - 1.22 |

| HDPE | High-density polyethylene | 0.97 |

| LDPE | Low-density polyethylene | 0.93 |

| PA66 | Nylon 66 | 1.14 |

| PA6 | Nylon 6 | 1.14 |

| PBT | Polybutylene terephthalate | 1.30 |

| PC | Polycarbonate | 1.2 |

| PC-ABS | ABS polycarbonate | 1.15 |

| PET | Polyethylene terephthalate | 1.38 |

| PMMA | Polymethyl methacrylate (acrylic) | 1.19 |

| POM | Acetal polyoxymethylene | 1.42 |

| PP | Polypropylene | 0.91 |

| PPS | Polyphenylene sulfide | 1.35 |

| PS | Polystyrene | 1.07 |

| TPE | Thermoplastic elastomer | 0.95 |

| TPV | Thermoplastic vulcanizates | 0.92 - 1.04 |