Best Tool & Engineering's Services

Tool Manufacturing Services

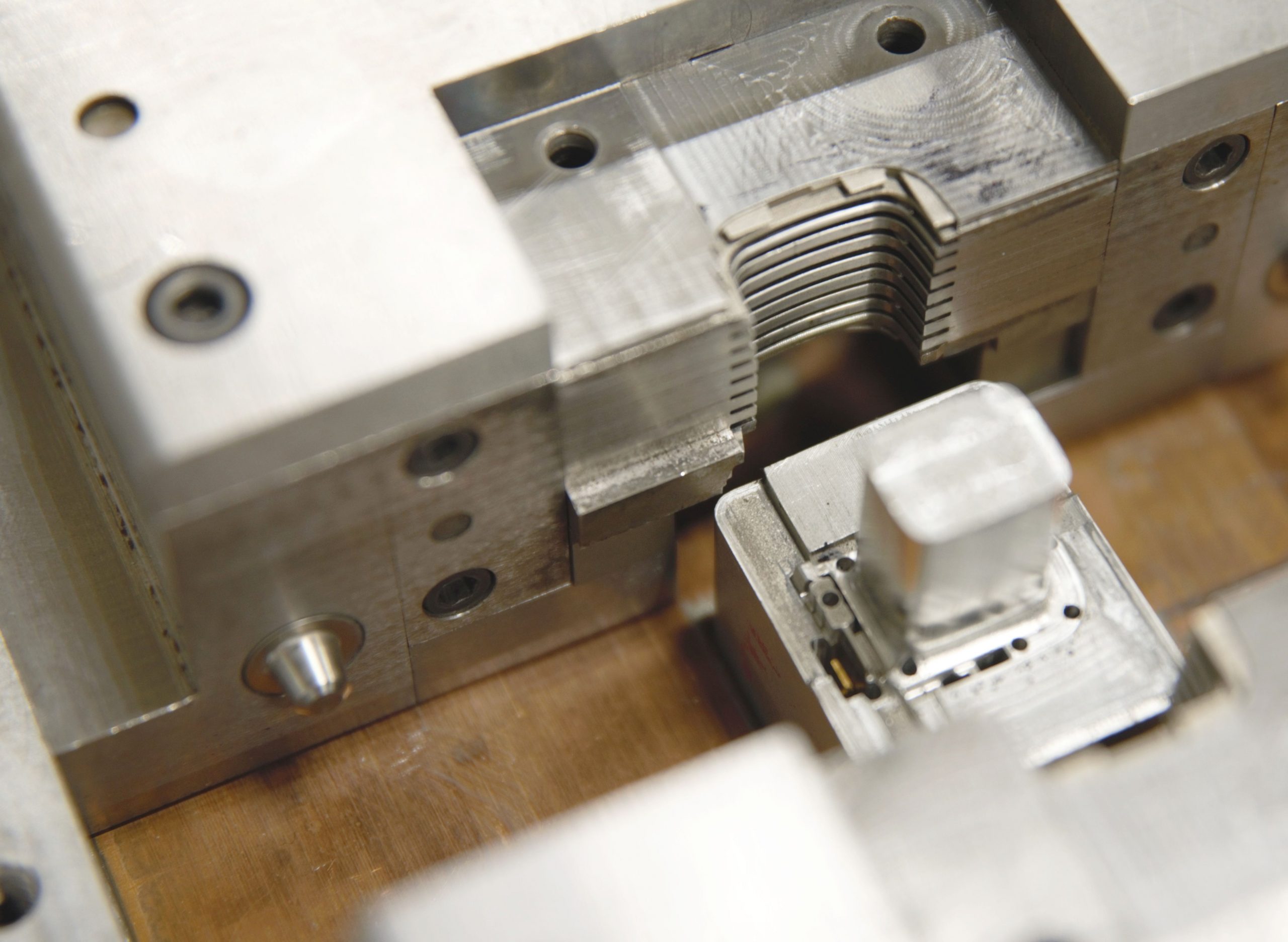

At Best Tool & Engineering, we provide full-service tool manufacturing with expertise in:

- Injection Molds

- Vibration Welding Tooling

- Hot Plate Welding Tooling

- Check Fixtures

Our primary material is aluminum, though we are equally experienced with steel. With an in-house machine shop, we maintain full control over quality, consistency, and tool longevity.

You wouldn’t buy a Lamborghini just to drive across town—our tools are built with the same mindset: engineered for performance, not compromise.

Thanks to vertically integrated design and manufacturing, we’ve developed proprietary features that enable our soft tooling to exceed industry-standard life cycles.

Capabilities

Capacity

Best Tool & Engineering is always expanding its capabilities. We’re able to maintain tolerances of ±0.0005 inches to ensure your parts are made with precision and are exactly as designed. Along with the standard machine shop equipment, our current machine capabilities are below:

- (6) 3-axis CNC machines – up to 32H X 32W X 84L

- (2) 5-axis CNC machines – up to 12H x 24W x 32L

- (1) CNC Lathe – 10” diameter cap

- (1) Wire EDM – up to 30° tapers with tolerances of ± 3 µm

Additional Features

Tools come in all sorts of shapes and sizes with many different features and capabilities. Here are some of the options Best Tool & Engineering provides with every tool:

- Electrical, Hydraulic, and Pneumatic integration

- Texturing

- Engraving

- Heat Treat

- Anodization

- Black Oxide

- Ren Board Prototypes (Vibration & Hot Plate Welding)