Case in Point: Not So Simple Clip

"Should be a walk in the park..."

Sometimes our human hubris gets in our way. We take a look at something and think, “that looks easy! There’s no way it’s that complicated.” Only to be very humbled once you realize how intricate it can be.

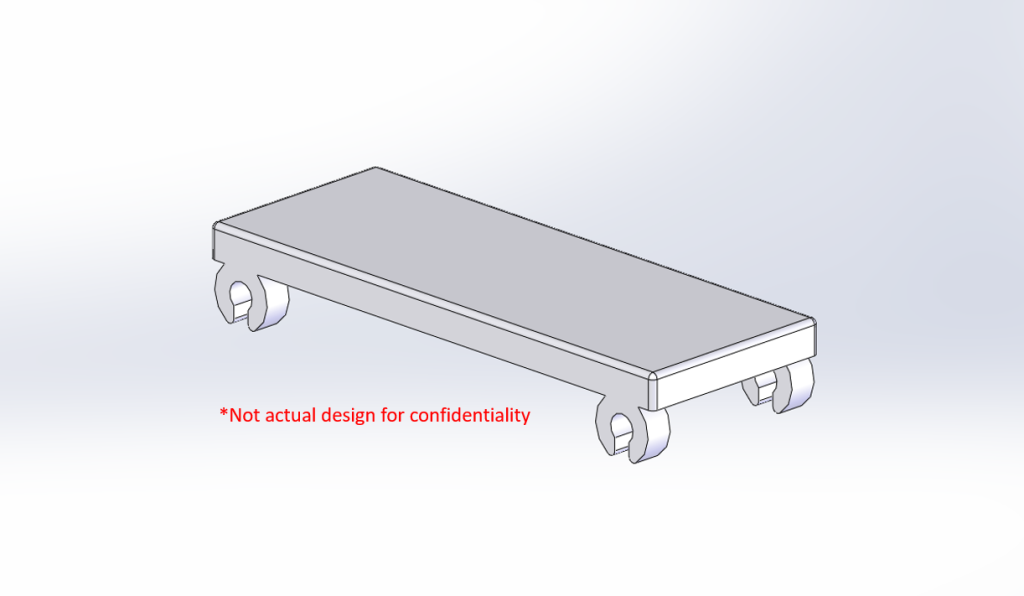

We were awarded a 16 cavity tool for a medical device. The device clips onto some baskets that are put in a washing machine to tell personnel if the surgical tools were properly sterilized.

It was an existing product for the customer, but they were having scrap issues with their current supplier. As they couldn’t get the tooling from their supplier, they supplied us with a reverse-engineered 3D model of the existing part, along with a print that had dimensions that did not match the model.

Measuring the actual part showed the 3D model as accurate and we proceeded with the build.

Issue #1

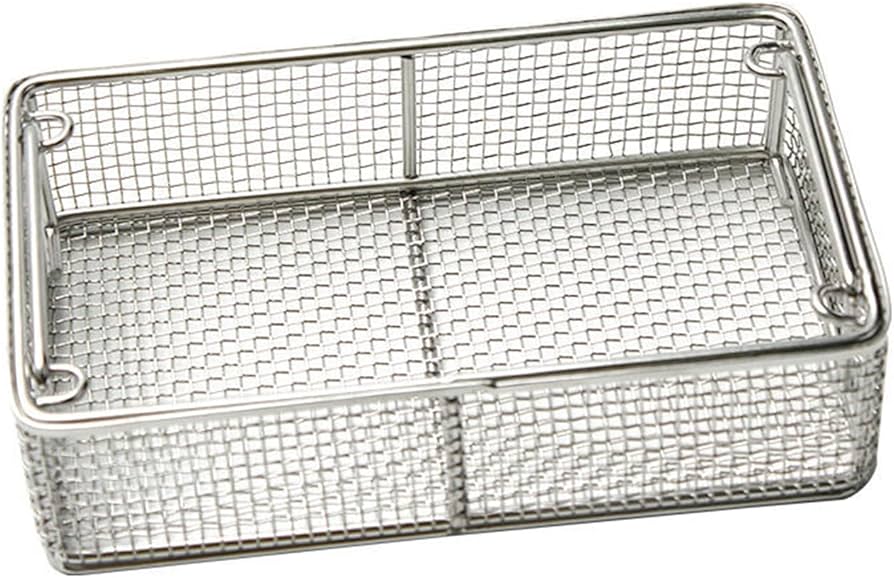

After molding initial samples, all looked well. The customer confirmed they were good. Not long after, we received the first complaint. These parts had clips that fastened onto some wire baskets. They were fastened to the wire baskets by hand.

With employees assembling hundreds if not thousands per day, they learned that the clipping took more effort than the original parts. We built the tool to the model, but not only was the print supplied incorrect, there was no dimensioning on the clip feature. We had assumed general tolerances.

Issue #2

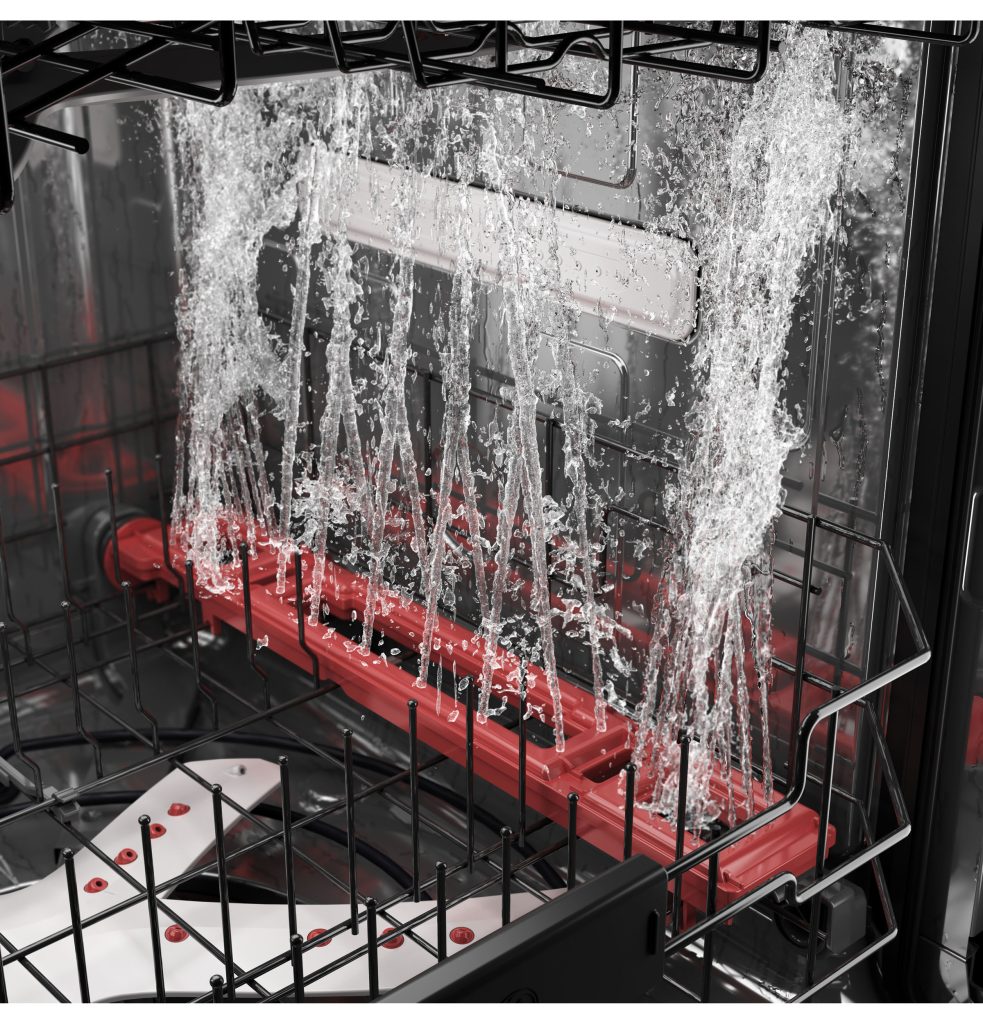

We loosened them up a few thousandths. Molded some more parts. And soon received the second complaint: the clips were now too loose.

The effort to install them was reduced, but now when the parts went through the washing machine, the jets blew them off. We dialed in our numbers and fixed the problem.

Issue #3

The final complaint that arose was the part did not bend the way it should when installed. This bend in the part was critical in verifying the surgical tools were sterilized from the wash. We launched an investigation into the tolerances of the affected areas and modified the mold.

Case in point? Make sure you understand the tolerances you need for fit and function. How tight is too tight? How loose is too loose? For ergonomics, this is a must.