Case Study: You can’t put lipstick on a pig!

Give us your tired, your poorly designed molds, your huddled messes yearning to run parts at cycle and actually make you money.

This playful twist on Emma Lazarus’s iconic poem The New Colossus (inscribed on the pedestal of the Statue of Liberty) perfectly captures what it feels like when customers bring us molds that everyone else has given up on.

Recently, a mold came in that had everyone shaking their heads. It was running on a four-minute cycle, with no guide pins, poor water lines, and flash all over the part.

The first thing we noticed was the tool had no guide pins. Guide pins are what allow the mold to open and close precisely. Without them, you’re relying on the operator to set the mold properly in the press and for the press to accurately open and close. For most shops, these are two huge areas of error. Because of the lack of guide pins, the mold wasn’t opening and closing properly so the two halves weren’t lining up causing plastic to squeeze out in areas it shouldn’t i.e. flash.

So, we machined dielocks into the sides of the bottom half to compensate for the lack of guide pins—aligning the two halves together and dramatically reducing flash.

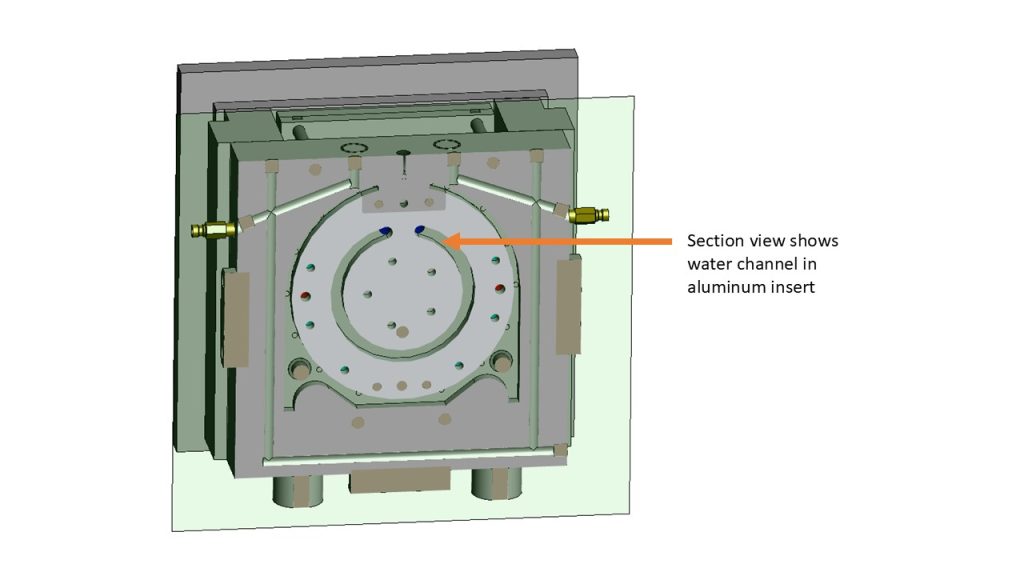

Next, we reviewed the water lines which were completely inadequate. Because of the lack of real estate to do anything, we added water directly into the center core by machining a channel into the bottom insert—a conformal cooling approach. And since the material was TPV, we were able to make the insert in aluminum, which allowed for faster thermal transfer.

With these changes alone, we brought the cycle time down from four minutes to just 90 seconds. A 60% improvement.

We then added a steel subgate insert for longevity, allowing the mold to run automatically. It previously had a sprue gate with a runner that needed to be manually cut off from the part.

All of this was accomplished within seven days—without building a new mold.

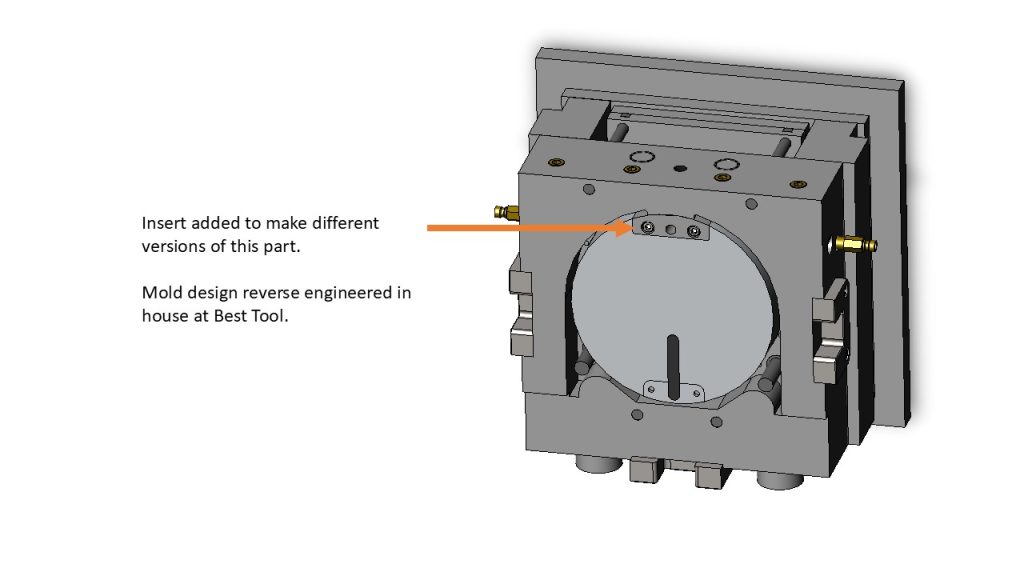

Afterward, we found out the customer had another version of the part that required sawing off a piece of the part. So, we made an insert so they could mold the modified part—saving them a costly manual process.

We also doubled the number of ejector pins, allowing us to eject the part faster. Part of the reason for the original cycle time was you had to wait for the part to cool before the ejector pins could push the part out. If you didn’t wait, they’d push into the hot part causing deformaties.

We’ve always said you can’t put lipstick on a pig—and sure enough, a week later, the pig went to prom.

If you’ve got a mold that just won’t behave, don’t discount it. Give it to us for a look—we’ll repair it, run it in-house, and make sure it’s truly production-ready before it goes back out the door.