Fix this First: Medical Component

From impossible to possible, we recommend a simple change to make a previously difficult product functional.

I was called by a customer regarding some new products they were interested in taking to market.

A 10-minute drive later, I stepped into the customer’s office to meet the design team.

After introductions, they showed me a medical device that was going to end up very similar to one we were already molding now, and they had questions about the manufacturability of it.

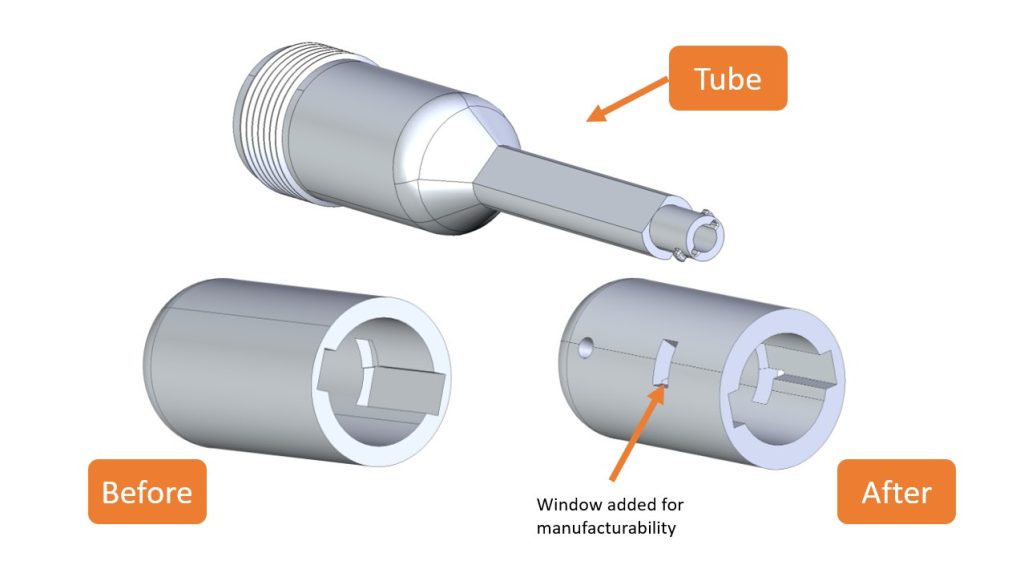

Upon first glance, everything seemed to be fine. It was a tube with some caps on both ends. Pretty simple.

Then we started looking more at the cap. Originally, the concept had been a threaded cap, so I asked them what their volumes were. They responded that they were about 1,000 per year.

Plastic parts with threads tend to cost more in tooling as they require special unscrewing mechanisms, or components, to be built into the mold. The more moving parts your mold has, the more money it will cost to make.

Aesthetics were important to this customer, and they wanted the part to look clean and sleek while maintaining its functionality. I recommended a simple twist cap and they gave me a .STEP file to review.

I took that design to DME, an industry leader for injection mold components. One product they make are called collapsible cores. Although they’re a special mold component, they can be cost effective for producing undercuts. You can read more about them here. They informed me that the part was too small for a collapsible core, and due to its size, traditional lifters would be either at best another expensive solution, or at worst, impossible.

I returned to the engineering team and told them they could put windows in the cap, and that would allow us to use slides to make the part. After some back and forth about part aesthetics and functionality, they agreed to put windows in the cap. This new design now simplified the tooling to justify a build at 1000 parts/year.

As this was for an existing and trusted customer, the consultation was done at no cost to them.

We do also offer free consultation to new projects and customers, but this is on limited availability. If you have a project in the design stage that you’d like us to review from a manufacturability / cost standpoint, you are free to give us a call and ask if we have available consulting time!